| Sign In | Join Free | My adobecards.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My adobecards.com |

|

Brand Name : LiQi

Model Number : OEM

Certification : ISO,GE

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 100000 Piece/Pieces per Month

Delivery Time : 35-50 days

Packaging Details : Wooden case

Mould core material : P20/ H718 /S136

Surface treatment : Plating

Shaping Mode : Custom Injection Mold

Mould cavity : Custom Cavity

Design software : X-T/ STP

Mold Life : 250000-500000shots

High Precision Plastic Custom Injection Mold Products Makers

Custom Injection Mold Information:

| Mold information | High Precision Plastic Custom Injection Mold Products Makers |

| Product Material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME you can choose |

| Cavity material | 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc |

| Runner | Cold/Hot runner |

| Cavity | Multi or single cavity |

| Standart parts | Hasco |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Treatment | Heat treatment and Nitriding,polish ect. |

| HRC | H45~52 |

| Tooling lifespan | 300,000-1,000,000 shots |

| Machine type | 90~650Ton |

| The standard of appearance of the products for stripe | MT(Mold Tech),YS,HN series |

| Lead time | 15~30 days |

How Does Plastic Injection Mould Work?

The manufacturing process for molded parts is complex. Before your parts are even molded, we're there to help you with comprehensive manufacturability feedback and consultative design services, so you can avoid mold design pitfalls before the resin hits the mold. From there, our production process is documented and optimized using scientific molding so you get high-quality parts consistently and reliably with every production run.

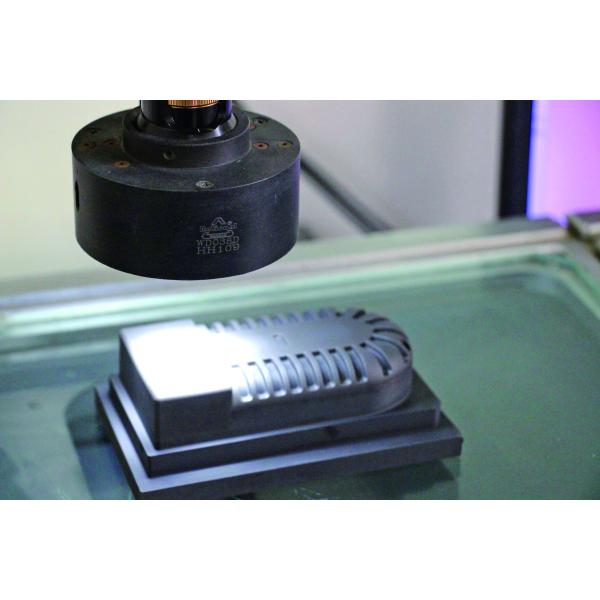

Critical-to-quality (CTQ) dimensions you call out on models let us know what areas are most crucial to the success of your parts. Once the parts start molding, the process and samples are qualified using automated inline CMM technology, generating a detailed FAI and process capability study with no additional lead time.

Our thermoplastic injection molding is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. As part of the scientific molding process, our molders independently optimize and monitor fill speed, hold pressure, and hold time, and periodically inspect part quality and cosmetics. During the molding process, we use an automated inline CMM to ensure dimensional accuracy, as well as generate a detailed process capability study and FAI report.

|

|

Custom Cavity S136 Precision Plastic Injection Moulding Plating Surface Images |