| Sign In | Join Free | My adobecards.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My adobecards.com |

|

Brand Name : LiQi

Model Number : OEM

Certification : ISO,GE

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 100000 Piece/Pieces per Month

Delivery Time : 35-50 days

Packaging Details : Wooden case

Processing Service : Moulding

Mould life : 300000-500000shots

Color : Blue or Customized

Prototype Process : SLA, vacuum forming, CNC, etc

Size : According to your drawings

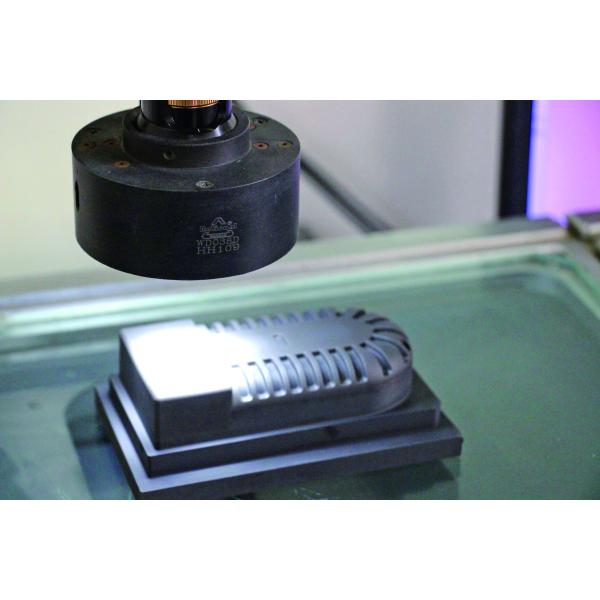

Product name : High Performance Plastic Polypropylene Injection Molding Heat Resistant

Product : Household Product

Extrusion Molding Polypropylene Injection Molding Blow Molding

| Mold Name | Extrusion Molding Polypropylene Injection Molding Blow Molding |

| Mould Shaping | injection mold |

| De-mould Type | Automatic Eject (Ejector pin, Air gate, Ejector plate, Hydro-cylinder, etc) |

| Mould material | NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc |

| Mould base | 45#/according to customer’s requirements/ subject to specific mould |

| Mould Cavity | Single/multi |

| Sprue Gate | Hot runner, Cold runner, Pin-point gate, Submarine gate, etc |

| Design software | UG, PROE, CAD, CAXA ect. |

| Plastic material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect. |

| Mould life | 300,000-3,000,000 shots |

| Delivery time | 15-60 days |

| Payment Terms: | T/T or L/C |

| Packaging | Wooden Cases |

| Transportation | By Sea or by air |

| Export Country | worldwide |

| Specification | Depends on customer's requirements. |

| OEM order | welcome |

Specification:

Polypropylene is a polymer formed by addition polymerization of propylene. It is a white waxy material with a transparent and light appearance. The chemical formula is (C3H6)n, the density is 0.89~0.91g/cm3, It is flammable, with a melting point of 189℃, softening at about 155℃, and the use temperature range is -30~140℃ . It is resistant to corrosion by acids, alkalis, salt solutions and a variety of organic solvents below 80°C, and can be decomposed under high temperature and oxidation. Polypropylene is widely used in the production of clothing, blankets and other fiber products, medical equipment, automobiles, bicycles, parts, pipelines, chemical containers, etc. It is also used in food and pharmaceutical packaging.

Polypropylene Injection Molding is a commonly used plastic injection molding material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties and provides Polypropylene Injection Molding terpolymer with a robust combination of features.

Advantages:

Polypropylene is a polymer formed by addition polymerization of propylene. It is a white waxy material with a transparent and light appearance. The chemical formula is (C3H6)n, the density is 0.89~0.91g/cm3, It is flammable, with a melting point of 189℃, softening at about 155℃, and the use temperature range is -30~140℃ . It is resistant to corrosion by acids, alkalis, salt solutions and a variety of organic solvents below 80°C, and can be decomposed under high temperature and oxidation. Polypropylene is widely used in the production of clothing, blankets and other fiber products, medical equipment, automobiles, bicycles, parts, pipelines, chemical containers, etc. It is also used in food and pharmaceutical packaging.

Our Advantages:

1. Professional experienced manufacturer for many years

2. Competitive price from factory

3. Timely and short lead time

4. OEM & ODM are welcome

FAQ:

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then mass production after samples comfirmed.

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.

|

|

Extrusion Polypropylene Injection Molding , NAK80 Injection Molding Multiple Cavities Images |